FORTIFIED BUILDING SOLUTIONS

CONCREWALL SCIP CONSTRUCTION

BUILT TO ENDURE, DESIGNED TO LAST.

Choose your role to receive tailored insights; whether you’re a homeowner seeking comfort, a building professional pursuing excellence, or an industry leader curious about SCIP manufacturing or distribution. Let’s build your vision together.

FORTIFIED BUILDING SYSTEM

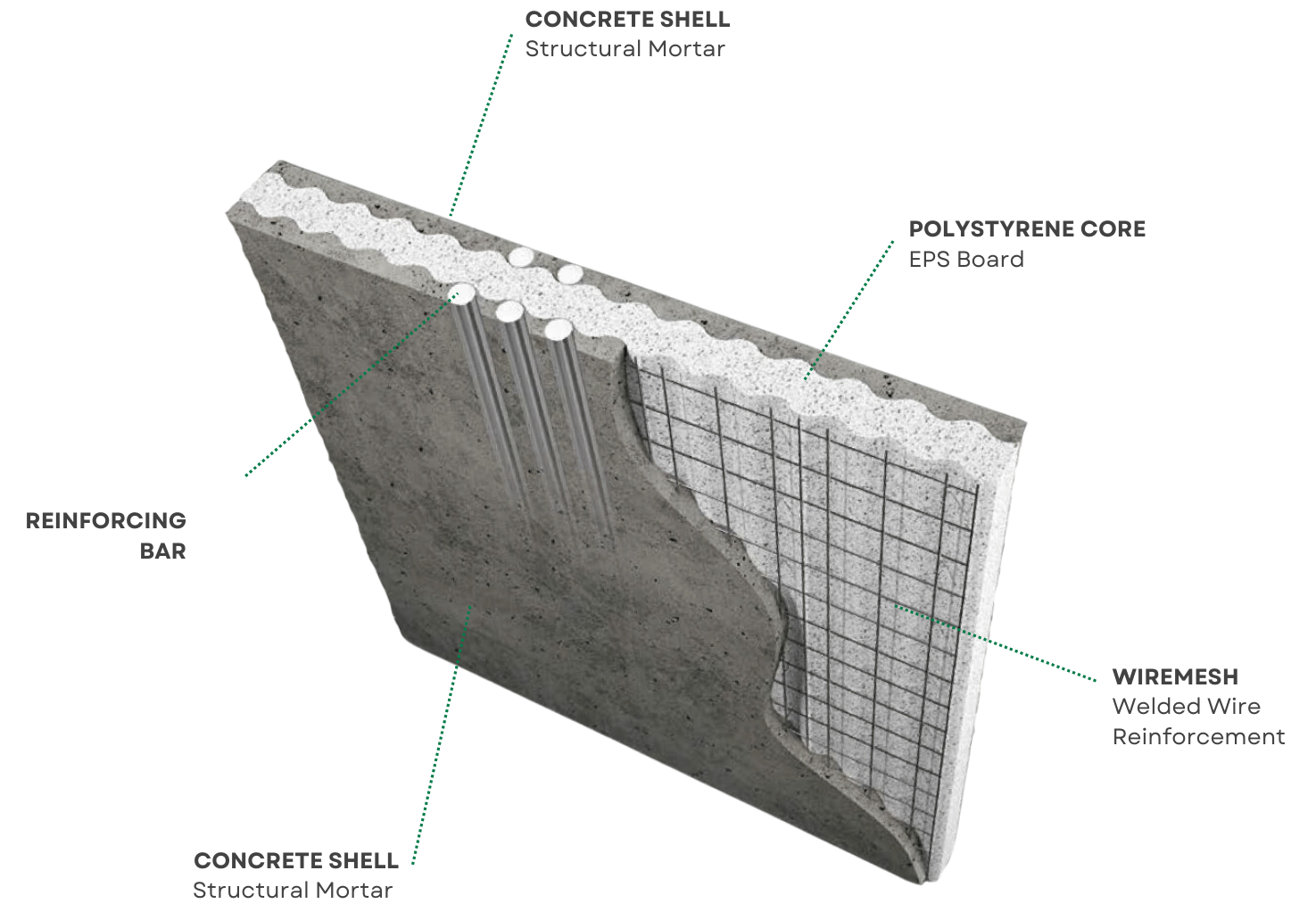

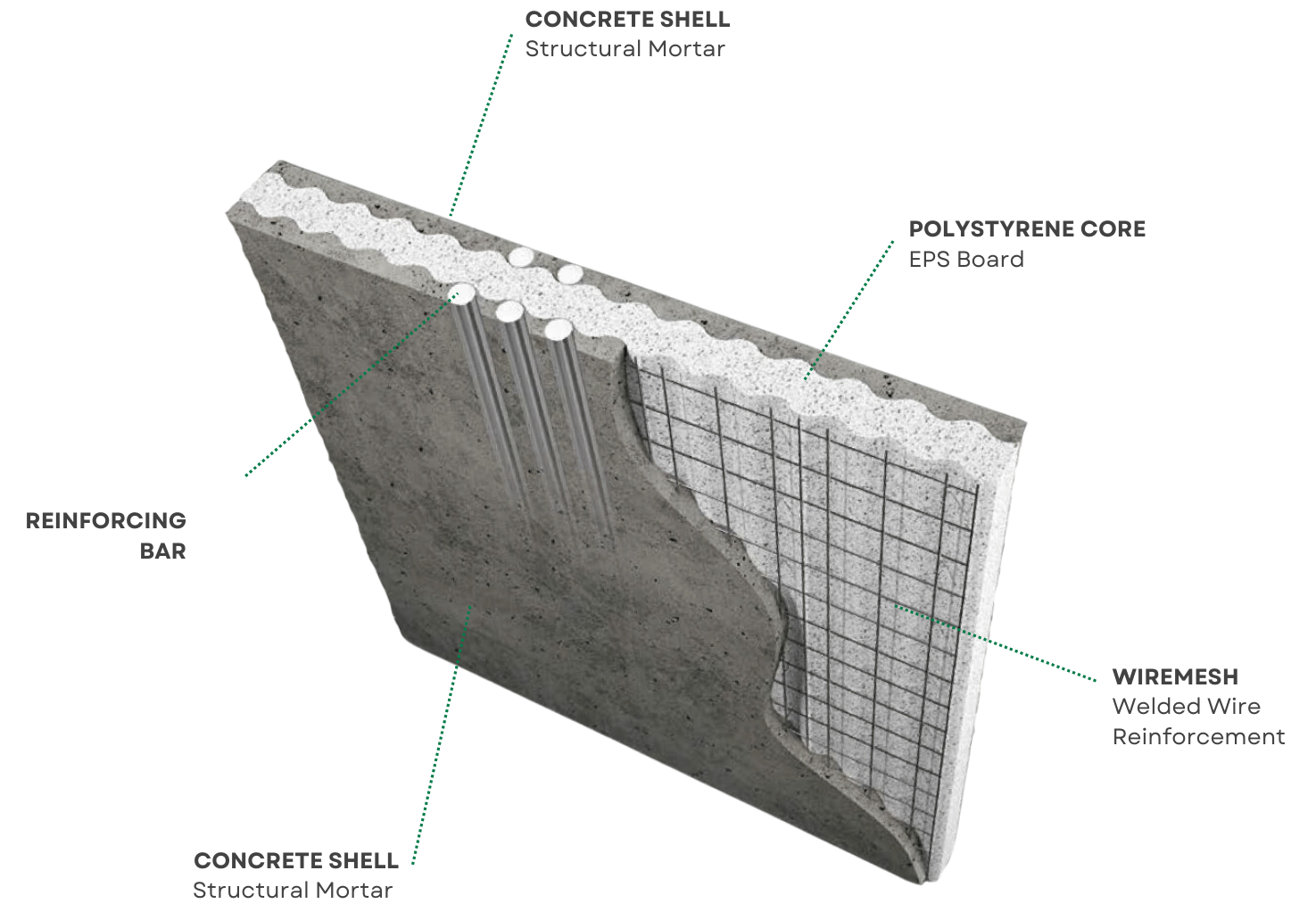

STRUCTURAL CONCRETE INSULATED PANELS

The polystyrene panel combined with the wire mesh provides the structural framing component of your project. This is more than a wall system. It’s the entire framing package.

PRODUCT TECHNOLOGY

WE OFFER A SUPERIOR

SCIP SOLUTION

Concrewall SCIP panels are expertly crafted using cutting-edge SCHNELL machinery. Our exclusive partnership with SCHNELL ensures the production of top-quality SCIP materials, only available at Concrewall locations.

Seeking a fortified solution for your project? Let’s build together!

7 STEPS TO A FORTIFIED STRUCTURE

THE COMPLETE BUILDING ENVELOPE

CONSTRUCTED TO LAST GENERATIONS

REDUCE THE COST OF OWNERSHIP

Concrewall’s holistic approach to construction seeks to create buildings that are economically sustainable and provide a secure and resilient living environment for the homeowners.

INSURANCE SAVINGS

Concrete structures are considered more durable and resistant to natural disasters such as hurricanes, which can make them more attractive to insurance providers. Insurance providers also recognize the added protection that concrete construction can provide against high winds, flooding, and fire, which are common risks in many communities. This is reflected in the average insurance quote for concrete buildings compared to the average quote in wood buildings.

UTILITY SAVINGS

Concrete construction is known for its excellent thermal mass properties, meaning it can regulate indoor temperatures, reducing the need for heating and cooling systems. This can lead to lower energy bills for homeowners and businesses.

MAINTENANCE SAVINGS

Concrete structures are less susceptible to mold and mildew growth, reducing the risk of health hazards and maintenance costs associated with mold remediation. Furthermore, a concrete home is a fortified home able to withstand the extreme weather events, is less likely to suffer damage from natural disasters, and increases the peace of mind for its occupants.

Concrewall USA Headquarters is located in Panama City, Florida and we have the capability of servicing coast to coast. Our industry experts are here to provide training and guidance for the architects, structural engineers, and contractors involved in your project. Let’s connect!

Insurance Premiums Explained

The cost of homeowner’s insurance rates in Florida can vary depending on several factors: 1) the home’s proximity to the coast2) the method of construction 3) the type of roof 4) the homeowner’s coverage options Florida is known for its high risk of natural disasters...

Insurance Premiums Explained

The cost of homeowner’s insurance rates in Florida can vary depending on several factors: 1) the home’s proximity to the coast2) the method of construction 3) the type of roof 4) the homeowner’s coverage options Florida is known for its high risk of natural disasters...

CONCREWALL FAQ’s

What is SCIP?

Concrewall produces panels that consists of a polystyrene sheet assembled together with welded wire mesh called Structural Concrete Insulated Panels (SCIP). We use best-in-class Schnell Home machinery to produce our SCIP panels.

Learn more about our SCIP products here.

What construction applications can the Concrewall system be used for?

Concrewall Structural Concrete Insulated Panels can be used for many construction applications, including Residential, Industrial, Commercial, Multi-Story Housing, Public Buildings, Federal/Military projects, and other buildings (fences, swimming pools, bust stops, etc.).

What is the difference between SCIP and ICF construction?

SCIP (Structural Concrete Insulated Panels) construction and ICF (Insulated Concrete Form) construction are both methods used in the construction industry to create energy-efficient and durable buildings. While they share some similarities, there are several key differences between the two.

Here are seven differences:

Construction Technique

Insulation Method

Structural Integrity

Construction Time

Construction Cost

Building Envelope

Design Flexibility

Learn more about differences between SCIP and ICF construction here.

What sets Concrewall apart from other SCIP manufacturers?

Concrewall USA has an exclusive partnership with The Schnell Group of Italy. Concrewall manufactures Structural Concrete Insulated Panels (SCIP) exclusively in North America using best-in-class Schnell Home machinery.

Our team’s industry expertise, reliability, and personalized approach make us a trusted choice for construction projects of any scale.

What areas does Concrewall serve?

Concrewall USA Headquarters is located in Panama City, Florida and we have the capability of servicing coast to coast.

What aspects of a construction project does Concrewall handle?

Concrewall manufactures Structural Concrete Insulated Panels (SCIP) design-to-order for qualifying projects. To ensure the integrity of the SCIP building system and quality of results, we may provide comprehensive construction services, including structural design assistance, workforce training, subcontractor solutions, and post-construction support.

Is the Concrewall system code compliant?

Concrewall has carried out many different laboratory tests that certify the numerous qualities of the panels.

- Hurricane Debris Missile Impact Test: The Single Panels successfully passed the missile tests with estimated wind speeds around 320 km/h – 200 mph

- Fire Resistance Test

- Acoustic Isolation Test

- Floor Panel Bending Test: Single Panel 400 cm x 400 cm was progressively loaded towards the breaking point which corresponds to a uniformly distributed nominal load well over 2000 kg/m2. The test was done by slowly filling a water tank measuring 300 cm x 300 cm and 200 cm high.

- Mechanical Resistance Test – Compression and Shear: The minimum value from the results of the testing for breakage under compression was 70 tons. This means that the Single Panel is able to support the loads from a six storey building. Single Panel with 3 cm of shotcrete per side = 20 MPa = 3000 PSI.

- Thermal Transmittance Test

Concrewall SCIP products meet all NOA Requirements and are approved for use in Miami-Dade County. ICC Evaluation Reports are also available for review.

View All FAQ’s >